Basic knowledge of cutting tools, this one is enough

Release time:

2020-06-29

A good horse needs to be equipped with a good saddle and use advanced numerical control processing equipment. If the tool used is wrong, it is useless! The selection of suitable tool materials has a great influence on the service life of the tool, the processing efficiency, the processing quality and the processing cost. This article provides dry goods about tool knowledge, collection and forwarding, learn together.

1. tool materials should have basic properties

The choice of tool material has a great influence on tool life, machining efficiency, machining quality and machining cost. Cutting tool to withstand high pressure, high temperature, friction, impact and vibration and other effects. Therefore, the tool material should have the following basic properties:

(1) Hardness and wear resistance. The hardness of the tool material must be higher than the hardness of the workpiece material, which is generally required to be above 60HRC. The higher the hardness of the tool material, the better the wear resistance.

(2) strength and toughness. The tool material should have high strength and toughness, so as to withstand the cutting force, impact and vibration, to prevent the tool brittle fracture and chipping.

(3) Heat resistance. The tool material has good heat resistance, can withstand high cutting temperature, and has good oxidation resistance.

(4) Process performance and economy. Tool materials should have good forging performance, heat treatment performance, welding performance; grinding performance, etc., and to pursue a high performance-to-price ratio.

Types, properties, characteristics and applications of 2. tool materials

1. Diamond tool material

Diamond, an allotropin of carbon, is the hardest material found in nature. Diamond tools have high hardness, high wear resistance and high thermal conductivity, and are widely used in the processing of non-ferrous and non-metallic materials. Especially in aluminum and silicon aluminum alloy high-speed cutting, diamond tools are difficult to replace the main cutting tool varieties. Diamond cutting tools, which can achieve high efficiency, high stability and long life, are indispensable and important tools in modern CNC machining.

(1) Types of diamond tools

Natural diamond tools: natural diamond as a cutting tool has a history of hundreds of years, natural single crystal diamond tools after fine grinding, cutting edge can be extremely sharp, cutting edge radius of up to 0.002μm, can achieve ultra-thin cutting, can be processed out of high precision and very low surface roughness, is recognized, ideal and can not be replaced by ultra-precision machining tools.

② PCD diamond tools: natural diamond is expensive, diamond is widely used in cutting or polycrystalline diamond (PCD), since the early 1970 s, the use of high temperature and high pressure synthesis technology to prepare polycrystalline diamond (Polycrystauine diamond, referred to as PCD blade developed successfully, in many cases natural diamond tools have been replaced by artificial polycrystalline diamond. PCD is rich in raw materials, and its price is only one tenth to one tenth of that of natural diamond. PCD tool can not be extremely sharp cutting edge, the surface quality of the workpiece is not as good as natural diamond, now the industry can not easily manufacture with chip breaker PCD blade. Therefore, PCD can only be used for fine cutting of non-ferrous metals and non-metals, and it is difficult to achieve ultra-precision mirror cutting.

③ CVD diamond tools: Since the late 1970 s to early 1980 s, CVD diamond technology has emerged in Japan. CVD diamond refers to the synthesis of diamond films on heterogeneous substrates (such as cemented carbide, ceramics, etc.) by chemical vapor deposition (CVD). CVD diamond has exactly the same structure and characteristics as natural diamond. The performance of CVD diamond is very close to that of natural diamond, which has the advantages of natural single crystal diamond and polycrystalline diamond (PCD), and overcomes their shortcomings to a certain extent.

The performance characteristics of diamond tools

Extremely high hardness and wear resistance: Natural diamond is the hardest substance that has been found in nature. Diamond has a very high wear resistance, processing high hardness materials, the life of the diamond tool for the carbide tool lO ~ 100 times, even up to several hundred times.

② has a very low coefficient of friction: the coefficient of friction between diamond and some non-ferrous metals is lower than that of other tools, the coefficient of friction is low, the deformation during processing is small, and the cutting force can be reduced.

The cutting edge is very sharp: the cutting edge of the diamond tool can be very sharp, and the natural single crystal diamond tool can be as high as 0.002 ~ 0.008μm, which can be used for ultra-thin cutting and ultra-precision machining.

4 has a high thermal conductivity: diamond thermal conductivity and thermal diffusion rate is high, the cutting heat is easy to dissipate, the tool cutting part of the low temperature.

⑤ has a low thermal expansion coefficient: the thermal expansion coefficient of diamond is several times smaller than that of cemented carbide, and the change of tool size caused by cutting heat is very small, which is particularly important for precision and ultra-precision machining with high dimensional accuracy requirements.

The application of diamond tools

Diamond tools are mostly used for fine cutting and boring of non-ferrous metals and non-metallic materials at high speed. Suitable for processing a variety of wear-resistant non-metal, such as glass steel powder metallurgy blank, ceramic materials, etc.; a variety of wear-resistant non-ferrous metals, such as a variety of silicon aluminum alloy; a variety of non-ferrous metal finishing.

The disadvantage of diamond tools is poor thermal stability, cutting temperature of more than 700 ℃ ~ 800 ℃, it will completely lose its hardness; in addition, it is not suitable for cutting ferrous metals, because diamond (carbon) at high temperatures easily interact with iron atoms, the carbon atoms into graphite structure, the tool is easily damaged.

2. Cubic boron nitride tool material

The second superhard material, cubic boron nitride (CBN), synthesized by a method similar to the diamond manufacturing method, is second only to diamond in terms of hardness and thermal conductivity, has excellent thermal stability, and does not oxidize when heated to 10000C in the atmosphere. CBN has extremely stable chemical properties for ferrous metals and can be widely used in the processing of steel products.

⑴ Types of cubic boron nitride cutting tools

Cubic boron nitride (CBN) is a substance that does not exist in nature. It can be divided into single crystal and polycrystalline, namely CBN single crystal and polycrystalline cubic boron nitride (Polycrystalline cubic bornnitride, referred to as PCBN). CBN is one of the alloisomers of boron nitride (BN) and is structurally similar to diamond.

PCBN (polycrystalline cubic boron nitride) is in high temperature and high pressure will be fine CBN material by bonding phase (TiC, TiN, Al, Ti, etc.) sintered together of polycrystalline material, is currently the use of synthetic hardness second only to diamond tool material, it and diamond collectively referred to as superhard tool material. PCBN is mainly used to make knives or other tools.

PCBN cutting tools can be divided into integral PCBN blades and PCBN composite blades sintered with cemented carbide.

PCBN composite blade is a layer of 0.5~1.0mm thick PCBN sintered on cemented carbide with good strength and toughness. Its performance has good toughness and high hardness and wear resistance. It solves the problems of low bending strength and welding difficulties of CBN blade.

⑵ The main properties and characteristics of cubic boron nitride

Although the hardness of cubic boron nitride is slightly lower than that of diamond, it is much higher than that of other high hardness materials. The outstanding advantage of CBN is that the thermal stability is much higher than that of diamond, which can reach more than 1200 ℃ (diamond is 700~800 ℃). Another outstanding advantage is that it is chemically inert and does not react with iron at 1200~1300 ℃. The main performance characteristics of cubic boron nitride are as follows.

① High hardness and wear resistance: CBN crystal structure is similar to diamond, with similar hardness and strength to diamond. PCBN is especially suitable for processing high hardness materials that can only be ground before, and can obtain better surface quality of the workpiece.

It has high thermal stability: the heat resistance of CBN can reach 1400~1500 ℃, which is almost l times higher than that of diamond (700~800 ℃). PCBN tool can be used than the carbide tool 3~5 times higher speed high-speed cutting high-temperature alloy and hardened steel.

3 excellent chemical stability: with iron materials to 1200-1300 ℃ also does not have a chemical effect, not as sharp as diamond wear, then it can still maintain the hardness of cemented carbide; PCBN tool is suitable for cutting hardened steel parts and chilled cast iron, can be widely used in high-speed cutting of cast iron.

4 has good thermal conductivity: although the thermal conductivity of CBN can not catch up with diamond, but in all kinds of tool materials, the thermal conductivity of PCBN is second only to diamond, which is much higher than that of high speed steel and cemented carbide.

⑤ has a lower coefficient of friction: low coefficient of friction can lead to the cutting force is reduced, the cutting temperature is reduced, the processing surface quality is improved.

⑶ Cubic Boron Nitride Tool Application

Cubic boron nitride is suitable for finishing all kinds of hardened steel, hard cast iron, high temperature alloy, hard alloy, surface spraying materials and other difficult cutting materials. The machining accuracy can reach IT5 (hole is IT6), and the surface roughness value can be as small as Ra1.25 ~ 0.20 μm.

Cubic boron nitride tool material toughness and bending strength is poor. Therefore, the cubic boron nitride turning tool should not be used for low speed, impact load roughing; at the same time not suitable for cutting plastic materials (such as aluminum alloy, copper alloy, nickel-based alloy, plastic steel, etc.), because the cutting of these metals will produce serious chip, and the processing surface deterioration.

3. Ceramic tool material

Ceramic cutting tools have the characteristics of high hardness, good wear resistance, excellent heat resistance and chemical stability, and are not easy to bond with metal. Ceramic cutting tools play a very important role in CNC machining, and ceramic cutting tools have become one of the main cutting tools for high-speed cutting and difficult-to-machine material processing. Ceramic tools are widely used in high-speed cutting, dry cutting, hard cutting and machining of difficult-to-machine materials. Ceramic tools can efficiently process high-hard materials that traditional tools cannot process at all, realizing "turning instead of grinding"; the best cutting speed of ceramic tools can be 2 ~ lO times higher than that of cemented carbide tools, thus greatly improving the cutting production efficiency; The main raw materials used in ceramic tool materials are the most abundant elements in the earth's crust, the popularization and application of ceramic cutting tools is of great significance to improve productivity, reduce processing costs and save strategic precious metals, and will greatly promote the progress of cutting technology.

(1) Types of ceramic tool materials

Ceramic tool material types can generally be divided into alumina based ceramics, silicon nitride based ceramics, composite silicon nitride alumina based ceramics three categories. Among them, alumina-based and silicon nitride-based ceramic tool materials are the most widely used. The performance of silicon nitride based ceramics is superior to that of alumina based ceramics.

The performance and characteristics of ceramic cutting tools

① High hardness, good wear resistance: Although the hardness of ceramic tools is not as high as PCD and PCBN, it is much higher than carbide and high-speed steel tools, reaching 93-95HRA. Ceramic tools can process high-hard materials that are difficult to process with traditional tools, and are suitable for high-speed cutting and hard cutting.

High temperature resistance, good heat resistance: ceramic tools can still be cut at high temperatures above 1200 ℃. Ceramic cutting tools have good high temperature mechanical properties, A12O3 ceramic cutting tools have particularly good oxidation resistance, and the cutting edge can be used continuously even if it is in a red hot state. Therefore, the ceramic tool can realize dry cutting, so that cutting fluid can be omitted.

The chemical stability is good: the ceramic tool is not easy to bond with the metal, and corrosion resistance, good chemical stability, can reduce the adhesive wear of the tool.

Low friction coefficient: ceramic tools and metal affinity is small, low friction coefficient, can reduce the cutting force and cutting temperature.

⑶ Ceramic knife has application

Ceramic is one of the tool materials mainly used for high-speed finishing and semi-finishing. Ceramic tools are suitable for cutting all kinds of cast iron (gray cast iron, ductile iron, malleable cast iron, chilled cast iron, high alloy wear-resistant cast iron) and steel (carbon structural steel, alloy structural steel, high strength steel, high manganese steel, hardened steel, etc.), can also be used to cut copper alloy, graphite, engineering plastics and composite materials.

The performance of ceramic tool materials has the problems of low bending strength and poor impact toughness, which is not suitable for cutting at low speed and impact load.

4. Coating tool material

Coating treatment is one of the important ways to improve tool performance. The emergence of coated tools has made a major breakthrough in cutting performance. Coated tools are coated with one or more layers of refractory compounds with good wear resistance on the tool body with good toughness. It combines the tool substrate with the hard coating, so that the tool performance is greatly improved. Coated cutting tools can improve processing efficiency, improve processing accuracy, extend tool life, and reduce processing costs.

About 80% of the cutting tools used in the new CNC machine tools use coated tools. Coated tools will be the most important tool varieties in the field of CNC machining in the future.

(1) Types of coated tools

According to different coating methods, coated tools can be divided into chemical vapor deposition (CVD) coated tools and physical vapor deposition (PVD) coated tools. Coated carbide tools generally use chemical vapor deposition method, the deposition temperature is about 1000 ℃. Coated high-speed steel tools generally use physical vapor deposition method, the deposition temperature is about 500 degrees C;

According to the different substrate materials of coated tools, coated tools can be divided into carbide coated tools, high-speed steel coated tools, and coated tools on ceramics and superhard materials (diamond and cubic boron nitride).

According to the nature of the coating material, coated tools can be divided into two categories, namely, "hard" coated tools and 'soft' coated tools. The main goal of "hard" coated tools is high hardness and wear resistance, and its main advantages are high hardness and good wear resistance, typically TiC and TiN coatings. The goal of "soft" coated tools is to pursue a low coefficient of friction, also known as self-lubricating tools. The coefficient of friction with the workpiece material is very low, only about 0.1, which can reduce bonding, reduce friction, and reduce cutting force and cutting temperature.

Recently nano-coated (Nanoeoating) tools have been developed. This coated tool can use a variety of different combinations of coating materials (such as metal/metal, metal/ceramic, ceramic/ceramic, etc.) to meet different functional and performance requirements. Reasonable design of nano-coating can make the tool material has excellent anti-friction and anti-wear function and self-lubricating performance, suitable for high-speed dry cutting.

(2) Characteristics of coated tools

Good mechanical and cutting properties: The coated tool combines the excellent properties of the substrate material and the coating material, which not only maintains the good toughness and high strength of the substrate, but also has the high hardness, high wear resistance and low friction coefficient of the coating. Therefore, the cutting speed of coated tools can be increased by more than 2 times compared with uncoated tools, and a higher feed rate is allowed. The life of the coated tool is also improved.

The versatility of the coating tool is wide, the processing range is significantly expanded, a coating tool can be used instead of several non-coated tools.

The coating thickness: with the increase of the coating thickness of the tool life will increase, but when the coating thickness reaches saturation, the tool life is no longer significantly increased. When the coating is too thick, it is easy to cause peeling; when the coating is too thin, the wear resistance is poor.

④ heavy grinding: coating blade heavy grinding poor, complex coating equipment, high process requirements, long coating time.

The coating material: different coating materials, cutting performance is not the same. Such as: low speed cutting, TiC coating advantage; high speed cutting, TiN is more appropriate.

Application of coated cutting tools

Coated cutting tools have great potential in the field of CNC machining and will be the most important tool variety in the field of CNC machining in the future. Coating technology has been applied to end mills, reamers, drills, composite hole machining tools, gear hobs, gear shaper cutters, shaving cutters, forming broaches and various machine-clamped indexable inserts to meet the needs of high-speed cutting of various steel and cast iron, heat-resistant alloys and non-ferrous metals.

5. Carbide tool material

Carbide tools, especially indexable carbide tools, are the leading products of CNC machining tools. Since the 1980 s, the varieties of various integral and indexable carbide tools or inserts have been extended to various cutting tools. In the field of cutting tools, the indexable carbide tools have been expanded from simple turning tools and face milling cutters to various precision, complex and forming tools.

(1) Types of carbide cutting tools

According to the main chemical composition, cemented carbide can be divided into tungsten carbide based cemented carbide and carbon (nitrogen) titanium (TiC(N)) based cemented carbide.

Tungsten carbide-based hard alloys include tungsten cobalt (YG), tungsten cobalt titanium (YT), and rare carbide (YW). They have their own advantages and disadvantages. The main components are tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC), niobium carbide (NbC), etc. The commonly used metal bonding phase is Co.

Carbon (nitrogen) titanium-based hard alloy is a hard alloy with TiC as the main component (some add other carbides or nitrides), and the commonly used metal bonding phase is Mo and Ni.

ISO (International Organization for Standardization) divides cemented carbide for cutting into three categories:

Class K, including Kl0 ~ K40, is equivalent to China's YG class (the main component is WC.Co).

P class, including P01 ~ P50, is equivalent to China's YT class (the main component is WC.TiC.Co).

The M class, including M10 ~ M40, is equivalent to the YW class in China (the main component is WC-TiC-TaC(NbC)-Co).

Each grade represents a series of alloys from high hardness to maximum toughness with numbers between 01 and 50.

The performance characteristics of carbide cutting tools

① high hardness: cemented carbide cutting tool is made by high hardness and melting point of carbide (called hard phase) and metal binder (called bonding phase) by powder metallurgy method, its hardness of 89 ~ 93HRA, far higher than high speed steel, at 5400C, the hardness can still reach 82 ~ 87HRA, and high speed steel at room temperature hardness (83 ~ 86HRA) the same. The hardness value of cemented carbide varies with the nature, quantity, particle size of carbide and the content of metal bonding phase, and generally decreases with the increase of the content of metal bonding phase. When the content of the bonding phase is the same, the hardness of YT alloy is higher than that of YG alloy, and the alloy with TaC(NbC) has higher high temperature hardness.

Bending strength and toughness: The bending strength of commonly used cemented carbide is in the range of 900 ~ 1500MPa. The higher the metallic binder phase content, the higher the flexural strength. When the binder content is the same, the strength of YG (WC-Co) alloy is higher than that of YT (WC-TiC-Co) alloy, and the strength decreases with the increase of TiC content. Cemented carbide is a brittle material, and its impact toughness at room temperature is only 1/30~1/8 of high-speed steel.

Application of Common Cemented Carbide Cutting Tools

YG alloys are mainly used for processing cast iron, non-ferrous metals and non-metallic materials. Fine grain cemented carbide (such as YG3X, YG6X) has higher hardness and wear resistance than medium grain at the same cobalt content. It is suitable for processing some special hard cast iron, austenitic stainless steel, heat-resistant alloy, titanium alloy, hard bronze and wear-resistant insulating materials.

The outstanding advantages of YT cemented carbide are high hardness, good heat resistance, high temperature hardness and compressive strength than YG, good oxidation resistance. Therefore, when the tool is required to have higher heat resistance and wear resistance, the brand with higher TiC content should be selected. YT alloy is suitable for processing plastic materials such as steel, but it is not suitable for processing titanium alloy, silicon aluminum alloy.

YW alloy has the performance of YG, YT alloy, good comprehensive performance, it can be used for processing steel, but also can be used for processing cast iron and non-ferrous metals. If the cobalt content is appropriately increased, the strength of this kind of alloy can be very high, and it can be used for roughing and intermittent cutting of various difficult-to-machine materials.

6. High speed steel cutter

High Speed Steel (HSS) is a kind of high alloy tool steel with more W, Mo, Cr, V and other alloying elements. High-speed steel tools in the strength, toughness and technology and other aspects of excellent comprehensive performance, in the complex tool, especially in the manufacture of hole machining tools, milling cutters, thread tools, broach, cutting tools and other complex blade tool, high-speed steel still occupy the main position. High-speed steel tools are easy to grind out sharp cutting edges.

According to different purposes, high-speed steel can be divided into general-purpose high-speed steel and high-performance high-speed steel.

⑴ General-purpose high-speed steel cutter

General purpose high speed steel. Generally can be divided into two types of tungsten steel, tungsten and molybdenum steel. This kind of high speed steel containing (C) is 0.7~0.9%. According to the different tungsten content in steel, it can be divided into tungsten steel containing 12% or 18% W, tungsten molybdenum steel containing 6% or 8% W, and molybdenum steel containing 2% or no W. General-purpose high-speed steel has a certain hardness (63-66HRC) and wear resistance, high strength and toughness, good plasticity and processing technology, so it is widely used in the manufacture of various complex tools.

① Tungsten steel: The typical grade of general-purpose high-speed steel tungsten steel is W18Cr4V (W18 for short), which has good comprehensive performance and high temperature hardness of 48.5HRC at 6000C, which can be used to manufacture various complex tools. It has the advantages of good grindability and low decarburization sensitivity, but due to the high carbide content, uneven distribution, large particles, low strength and toughness.

2 tungsten and molybdenum steel: refers to a part of tungsten in tungsten steel with molybdenum instead of a high-speed steel. The typical grade of tungsten molybdenum steel is W6Mo5Cr4V2 (M2 for short). The carbide particles of M2 are fine and uniform, and the strength, toughness and high temperature plasticity are better than W18Cr4V. Another kind of tungsten molybdenum steel is W9Mo3Cr4V steel (W9), its thermal stability is slightly higher than that of M2 steel, bending strength and toughness are better than W6M05Cr4V2 steel, and it has good processability.

(2) High-performance high-speed steel cutting tools

High-performance high-speed steel refers to the general-purpose high-speed steel composition to add some carbon content, vanadium content and the addition of Co, Al and other alloying elements of the new steel, which can improve its heat resistance and wear resistance. There are mainly the following categories:

① High carbon high speed steel. High-carbon high-speed steel (such as 95 W18Cr4V), room temperature and high temperature hardness, suitable for manufacturing and processing of ordinary steel and cast iron, high wear resistance requirements of drill bits, reamers, taps and milling cutters, etc. or processing of harder materials, should not withstand large impact.

② high vanadium high speed steel. Typical brands, such as W12Cr4V4Mo,(EV4 for short), contain V increased to 3%-5%, have good wear resistance, and are suitable for cutting materials with great tool wear, such as fiber, hard rubber, plastic, etc., and can also be used for processing stainless steel, high-strength steel, high-temperature alloy and other materials.

Cobalt high speed steel. It is a cobalt-containing superhard high-speed steel, a typical brand, such as W2Mo9Cr4VCo8 (M42), with high hardness, its hardness can reach 69-70HRC, which is suitable for processing high-strength heat-resistant steel, high-temperature alloy, titanium alloy and other difficult-to-machine materials. M42 has good grindability and is suitable for making precision and complex tools, but it is not suitable for working under impact cutting conditions.

④ Aluminum high speed steel. It is an aluminum-containing superhard high-speed steel with typical brands, such as W6Mo5Cr4V2Al (501 for short), and its high-temperature hardness at 6000C also reaches 54HRC, and its cutting performance is equivalent to M42. It is suitable for manufacturing milling cutters, drill bits, reamers, gear cutters, broaches, etc. and is used for processing alloy steel, stainless steel, high-strength steel, high-temperature alloy and other materials.

⑤ nitrogen superhard high speed steel. Typical grades, such as W12M03Cr4V3N, referred to as (V3N), are nitrogen-containing superhard high-speed steel, hardness, strength, toughness and M42, can be used as a substitute for cobalt-containing high-speed steel, used for low-speed cutting of difficult-to-process materials and low-speed high-finish processing.

(3) Melting high speed steel and powder metallurgy high speed steel

According to different manufacturing processes, high-speed steel can be divided into smelting high-speed steel and powder metallurgy high-speed steel.

① smelting high-speed steel: ordinary high-speed steel and high-performance high-speed steel are manufactured by smelting method. They are made into cutting tools through smelting, ingot casting and plating rolling. The serious problem of melting high-speed steel is carbide segregation, hard and brittle carbides are not evenly distributed in high-speed steel, and the grains are coarse (up to tens of microns), which has a negative impact on the wear resistance, toughness and cutting performance of high-speed steel tools.

② Powder metallurgy high speed steel (PM HSS): Powder metallurgy high speed steel (PM HSS) is a molten steel melted in a high-frequency induction furnace, atomized with high-pressure argon or pure nitrogen, and then quenched to obtain a fine and uniform crystal structure (high-speed steel powder), and then the obtained powder is pressed into a blank at high temperature and high pressure, or the blank is first made into a blank and then forged and rolled into a tool shape. Compared with high-speed steel manufactured by melting method, PM HSS has the advantages that the carbide grains are fine and uniform, and the strength, toughness and wear resistance are improved a lot compared with the melting high-speed steel. In the field of complex NC tool PM HSS tool will be further development and occupy an important position. Typical grades, such as F15, FR71, GF1, GF2, GF3, PT1, PVN, etc., can be used to manufacture large size, bear heavy load, large impact tools, can also be used to manufacture precision tools.

Selection Principle of 3. NC Cutting Tool Material

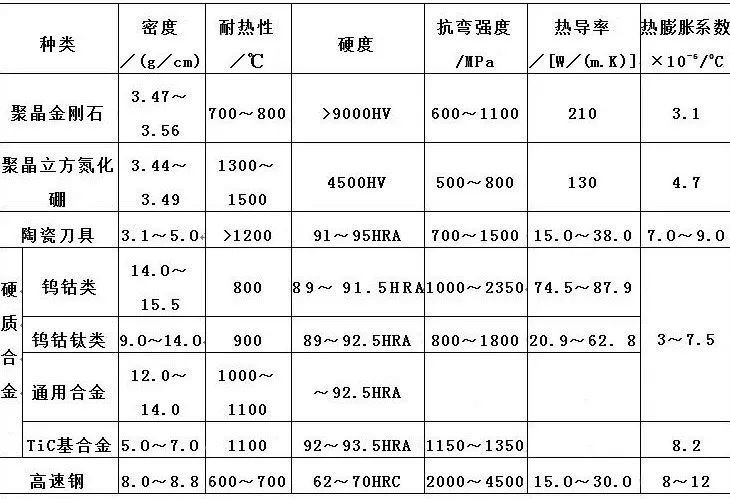

At present, the widely used CNC tool materials mainly include diamond tools, cubic boron nitride tools, ceramic tools, coated tools, carbide tools and high-speed steel tools. There are many total grades of tool materials, and their performance varies greatly. The following table shows the main performance indicators of various tool materials.

?

The main performance indicators of various cutting tool materials

?

?

The tool material for CNC machining must be selected according to the workpiece and the nature of the machining. The selection of tool materials should be reasonably matched with the processing object. The matching of cutting tool materials and processing objects mainly refers to the matching of mechanical properties, physical properties and chemical properties of the two, so as to obtain the longest tool life and the maximum cutting productivity.

1. Matching the mechanical properties of the cutting tool material and the machining object

The problem of matching the mechanical properties of the cutting tool and the processing object mainly refers to the matching of the mechanical properties parameters such as the strength, toughness and hardness of the tool and the workpiece material. Tool materials with different mechanical properties are suitable for processing different workpiece materials.

① Tool material hardness sequence: diamond tools> cubic boron nitride tools> ceramic tools> carbide> high speed steel.

The order of the bending strength of the tool material is: high-speed steel> cemented carbide> ceramic tools> diamond and cubic boron nitride tools.

The order of the toughness of the tool material is: high-speed steel> cemented carbide> cubic boron nitride, diamond and ceramic tools.

The workpiece material with high hardness must be processed with a higher hardness tool, and the hardness of the tool material must be higher than the hardness of the workpiece material, which is generally required to be above 60HRC. The higher the hardness of the tool material, the better its wear resistance. For example, when the amount of cobalt in cemented carbide increases, its strength and toughness increase, and its hardness decreases, which is suitable for roughing; when the amount of cobalt decreases, its hardness and wear resistance increase, which is suitable for finishing.

Cutting tools with excellent high-temperature mechanical properties are particularly suitable for high-speed machining. The excellent high temperature performance of ceramic tools enables them to cut at a high speed, and the allowable cutting speed can be increased by 2 to 10 times compared with cemented carbide.

2. The cutting tool material matches the physical properties of the processed object

Tools with different physical properties, such as high thermal conductivity and low melting point of high-speed steel tools, high melting point and low thermal expansion of ceramic tools, high thermal conductivity and low thermal expansion of diamond tools, etc., are suitable for the processing of workpiece materials are different. When machining workpieces with poor thermal conductivity, the tool material with good thermal conductivity should be used to make the cutting heat quickly pass out and reduce the cutting temperature. Due to the high thermal conductivity and thermal diffusion rate of diamond, the cutting heat is easy to dissipate and will not produce great thermal deformation, which is particularly important for precision machining tools with high dimensional accuracy.

① Heat-resistant temperature of various tool materials: diamond tools are 700 ~ 8000C, PCBN tools are 13000 ~ 15000C, ceramic tools are 1100 ~ 12000C, TiC(N)-based cemented carbide is 900 ~ 11000C, WC-based ultrafine grain cemented carbide is 800 ~ 9000C, HSS is 600 ~ 7000C.

The thermal conductivity of various tool materials: PCD>PCBN>WC-based cemented carbide> TiC(N)-based cemented carbide> HSS>Si3N4-based ceramics> A1203-based ceramics.

③ The order of thermal expansion coefficient of various tool materials is: HSS>WC-based cemented carbide> TiC(N)> A1203-based ceramics> PCBN>Si3N4-based ceramics> PCD.

④ The order of thermal shock resistance of various tool materials is: HSS>WC-based cemented carbide> Si3N4-based ceramics> PCBN>PCD>TiC(N)-based cemented carbide> A1203-based ceramics.

3. Matching the chemical properties of cutting tool materials and processing objects

The problem of matching the chemical properties of cutting tool materials and processing objects mainly refers to the matching of chemical properties parameters such as chemical affinity, chemical reaction, diffusion and dissolution of tool materials and workpiece materials. Different materials of the tool for the processing of the workpiece material is different.

① The anti-bonding temperature of various tool materials (with steel) is: PCBN> ceramic> cemented carbide> HSS.

The oxidation temperature of various tool materials is: ceramic> PCBN> cemented carbide> diamond> HSS.

The diffusion strength of the tool material (for steel) is: diamond> Si3N4 based ceramics> PCBN>A1203 based ceramics. The diffusion strength (for titanium) is: A1203 based ceramics> PCBN>SiC>Si3N4> diamond.

4. Reasonable choice of CNC tool materials

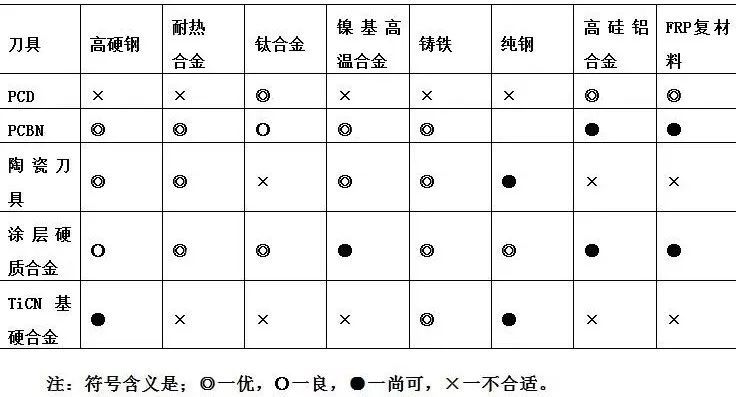

In general, PCBN, ceramic tools, coated carbide and TiCN-based carbide tools are suitable for CNC machining of ferrous metals such as steel, while PCD tools are suitable for the processing of non-ferrous metal materials such as Al, Mg, Cu and their alloys and non-metallic materials. The following table lists some of the workpiece materials that are suitable for machining with the above tool materials.

?

Some workpiece materials suitable for machining tool materials

?

Related News